Twenty years ago, commercial 3-Dimensional Printing was a fable only engineers gossiped about. Fast forward to present day, it has completely changed the world of so many different industries. Space research, medical treatments, manufacturing systems, and electronic production all have experienced refinements as a result of 3-D printers hitting the mainstream market. Plus, IT support has a whole new field to run diagnostics in! But if anything goes awry, they will probably tell you to try turning it off and on again. Since the rise of this new type of manufacturing, the scale of these printers has increased from the size of shoeboxes to garages. And the material choice has changed too. Scientists experiment with plastic, wood, concrete, titanium, and ceramic filament in order to produce a wide range of products. But are these printers going to become a household norm? We are unsure; however, they ARE going to drastically change (if they haven’t already changed) our manufacturing approach in the future!

To Boldly Go…

Space: The final frontier. These are the…new improvements 3-D printing has brought to the small satellite industry. Lockheed Martin, equipped with their garage sized 3-D printer, is now printing titanium domes to, “seal giant, high-pressure tanks that carry satellite fuel.” In traditional manufacturing, Lockheed has stated that more than 80% of materials will go to waste while making satellite domes; therefore, this new method of production cuts costs on time and material. And they REALLY cut down on time, from two years to three months actually. Plus, the International Space Station has its own 3-D printer and back-up equipment on board to make parts on-site. Turns out, it’s costly to outsource IT guys up there to fix broken technology.

Lockheed Martin: 3D Printed Titanium Dome

Lockheed Martin: 3D Printed Titanium Dome

Medical Advancements

The most important contribution 3-D printers have made to the field of medicine is the capability for patient-specific treatments. Before the introduction of this technology, surgical implants, spinal cord braces, dental aligners, and even hearing aid shells came in very few sizes. They wouldn’t always fit correctly for each person and often led to more discomfort. 3-D printers have changed the game. And thanks to body scans, printing implants and devices with intricate shapes has become an easier task. Similar to the satellite construction by Lockheed Martin, 3-D printing has decreased production time of medical devices, and it is also producing better results than before. Plus, 3-D organ printers are currently under research and being tested to help with heart, liver, and kidney transplantations. Now that’s pretty cool. But what’s next for 3-D printing?

A bioprinter developed 3D Bioprinting Solutions

A bioprinter developed 3D Bioprinting Solutions

Printing the Future

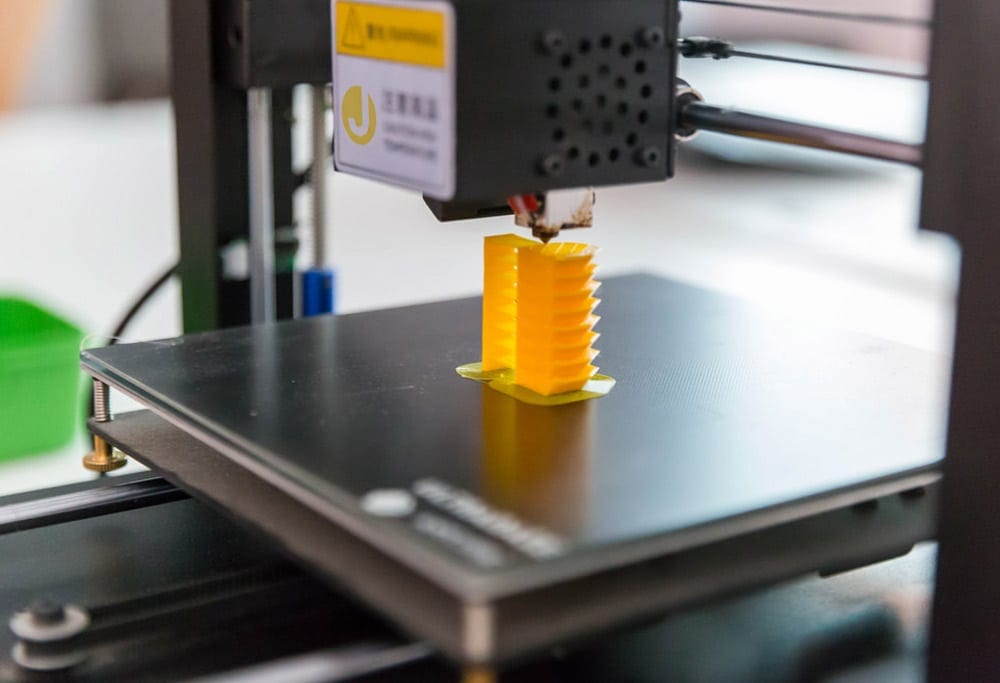

A decade ago, consumers weren’t really interested in the creations 3-D printers had to offer. They were made of a basic plastic, one color, and not exactly applicable in the real world. But now, 3-D printers can use all kinds of materials, like wood filament to construct architectural models or ceramic in order to create art straying away from traditional methods. 3-D printing is a costly practice, which is why there aren’t that many hobbyists out there in this field. However, there are startup companies that allow you to design your own part and they will print it for you with a small fee. Typically, 3-D printers are targeted toward businesses, but of course we can wonder if these handy machines will one day make their way into the typical household! (Many geek households are ahead of the game and have invested into their own 3-D printers!) That would be good news for us, because these printers work hand in hand with computers, which means some additional IT support from the guys down in the basement! So, here a few useful reasons people have bought 3-D printers for their homes!

Extra Income – Online stores, such as Etsy or eBay, are prime locations to sell unique 3-D printed gadgets! Obviously, you will have to start out buying your printer and filament, but who says you can’t put it to work to pay for itself?

Education – People who work in manufacturing or product design like to be able to sharpen their skills at home! It can be helpful to learn how the technology works and be able to run diagnostics on broken printers.

Gift Giving! – Personalized gifts are all the rage. You can make figurines, phone cases, and many other items.

3-D printing has drastically changed manufacturing over the last decade, and we are so excited, because there is even more potential for IT professionals to get out there and help! 3-D printed parts are helping people everyday through medical advancements, and they’re out-of-this-world assisting our astronauts over at the International Space Station! However, the most important creation 3-D printers have made are probably… more 3-D printers. Mind = Blown.

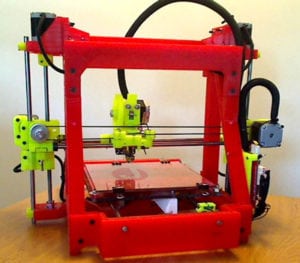

A 3-D printed 3-D printer named Little Red.

A 3-D printed 3-D printer named Little Red.

VIEW ALL